Blog & news

Eastern Cutting Corp. Featured in Concrete Openings Article

Eastern Cutting Corp. was featured on ConcreteOpenings.com cover article

Posted on March 9th, 2022

Precision Saw Cutting Required to Renovate Federal Building

The Jacob K. Javits Federal Building sits in the Civic Center neighborhood of Manhattan, New York City, and

is the home for a multitude of federal government agencies. The skyscraper towers at over 41 stories, and it is currently the tallest federal building not only in New York, but the United States. A project for the reconfiguration of the courtyard space at the Jacob K. Javits Federal Building planned to consolidate functions and meet the long-term needs of the Federal Bureau of Investigation, the U.S. Department of Health and Human Services and the U.S. Army Corps of Engineers.

Selective Demolition, Concrete Wall Sawing at Javits Building

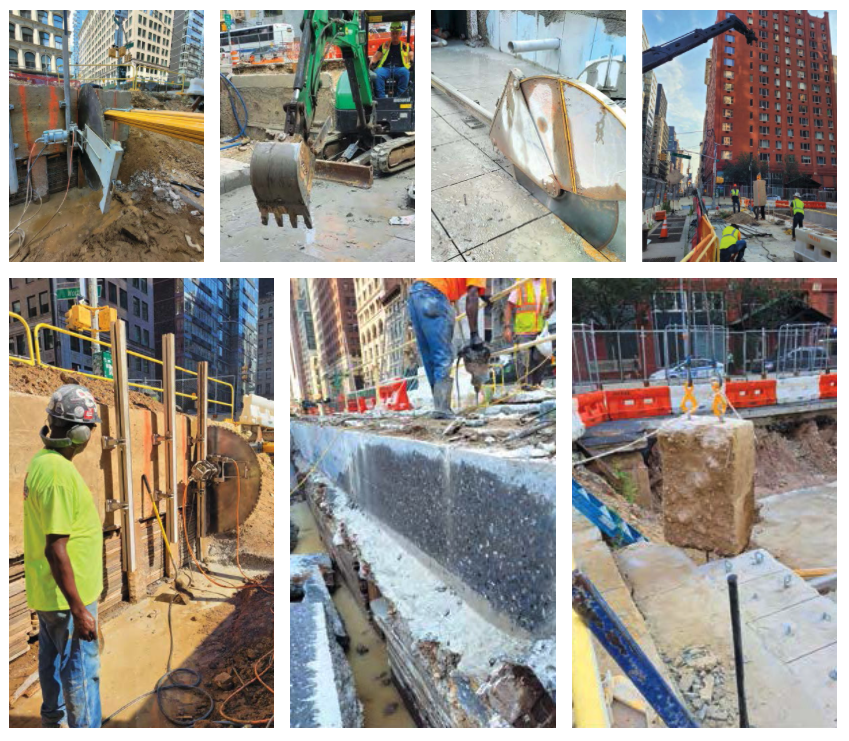

CSDA member Eastern Cutting Corp. was brought in by Volmar Construction, Inc. for the selective demolition of reinforced concrete roof slabs and large reinforced concrete support beams at the Javits Building. Eastern chose concrete cutting, specifically wall sawing, for its ability to quickly cut heavily reinforced concrete while reducing noise, dust and debris. Heavy equipment was not used due to limited access and the site’s proximity to the subway because of the weight limits and limited vibration near the tunnels. Jackhammering was also ruled out because of the large volume of removal needed, and the noise and vibration it entails. Hydrodemolition was used and tested on the site, but production rates were subpar.

The two Eastern operators began the project by wall sawing the roof slabs with a Pentruder 8-20HF wall saw into manageable 2’ x 3’ x 16” sections. Operators laid the large slabs into a checkboard-style layout, creating similar-sized cut sections for easy removal. Cut sections were then removed by a Bobcat mini excavator and placed into roll-off containers for disposal. A Real Power truck was used to power all the saw cutting equipment, eliminating the need for separate generators or additional equipment.

Eastern operators prepared for concrete beam sawing by first shoring up the beams by installing OSHA planks and shoring posts. Cutlines were snapped on the beam face ensuring each cut section would be at or under the appropriate weight limit for the crane. Before final cuts were made, a Hilti DD350 core drill was used to help install anchors, bolts and hooks on each cut section. Lifting was performed via a Magni RHT rotary telehandler crane from street level. Eastern operators had to calculate the weight of the cut sections and limitations of the crane being at street level was a major concern. In total, 58’ x 4’ x 5’ of beam was removed in 44 vertical saw cuts, with 75,000 square feet of 12-inch slab removed.

Overcoming Obstacles on the Construction Site

The proximity of the subway to the jobsite was an enormous obstacle on this project. The crane could not enter the site, so all the required lifting was done during non-peak weekend hours from street level to minimize disruption to vehicle and commuter traffic. Street and sidewalk closures were needed, which required coordination from the city and the GC. The GC’s safety coordinator held daily meetings with the crew and performed Job Safety Analyses (JSA) to update everyone on site of any changes and to prepare for the tasks of the day.

To everyone’s satisfaction, Eastern completed all work ahead of schedule. There was an additional project of a knee wall removal that was awarded to Eastern following the success of this project. At first glance, this looked like a project that would progress very slowly due to the numerous obstacles that were present. However, as it turned out, proper communication and great planning turned this project into one that was completed under time and without incident.

Eastern has a solid reputation and a professional staff that has executed similar projects in New York City. Volmar Construction has used Eastern’s services on previous jobs, and they continue to have a working relationship together.

Eastern Concrete Cutting Checks All the Boxes, Exceeds Expectations

Charlie Spinale, Superintendent of Volmar Construction, said about Eastern, “Finding the right contractors is key to staying on schedule and on budget. Eastern Concrete Cutting checks all the boxes. From estimating to coordination, they are a skilled field technician. Eastern met and exceeded all expectations. Eastern is and will continue to be my first call. The experience of this contractor in the field is priceless.”

Eastern Cutting Corp. has been a CSDA member since the company was founded, and their employees have always exemplified the spirit of the organization, by employing innovative thinking, advanced technology and collaboration to tackle any challenges that may arise.

COMPANY PROFILE

Eastern Cutting Corp. is headquartered in Bronx, New York, and was established in 2008. They have 12 trucks and 25 employees. The list of services they offer include wall sawing, wire sawing, robotic demolition and core drilling. They have been a member of CSDA since 2008.

RESOURCES

General Contractor

Volmar Construction, Inc.

CSDA Contractor

Eastern Cutting Corp.

Read the original article at Concrete Openings here.

Recent

- Eastern Cutting Corp. Featured in Concrete Openings Article

- Eastern Cutting Corp. Featured in Concrete Openings Article

- Need Concrete Cutting Services? Don’t DIY

- Eastern Cutting Corp. Featured in Brooklyn Paper Article

Categories

To learn more about the advantages of GPR, visit

www.CityScanCorp.com

To learn more about the advantages of GPR, visit

www.CityScanCorp.com As part of our continuation of improving service for our customers, Eastern has partnered with the leading concrete scanning company in the Tri-State area, CityScan Corp. Because locating embedded and buried hazards prior to concrete cutting, coring, breaking and excavating is an essential part in establishing a safe and cost effective construction site.